The industrial world is entering a new era where artificial intelligence is becoming just as critical as machinery itself. Maintenance, once seen as a reactive or routine task, is now an intelligent process driven by real-time data, predictive insights, and automation. AI tools are reshaping how factories, plants, and service teams handle repairs, manage assets, and sustain performance. From reducing downtime to optimizing maintenance schedules, artificial intelligence is not just improving efficiency—it’s redefining the entire philosophy of industrial operations.

From Reactive to Predictive Maintenance

Traditional maintenance relied heavily on fixed schedules or waiting for equipment to fail before taking action. This reactive approach often led to costly downtime, inefficiency, and unnecessary part replacements. AI has transformed this model by enabling predictive maintenance—using data to anticipate when machines will need attention before failure occurs.

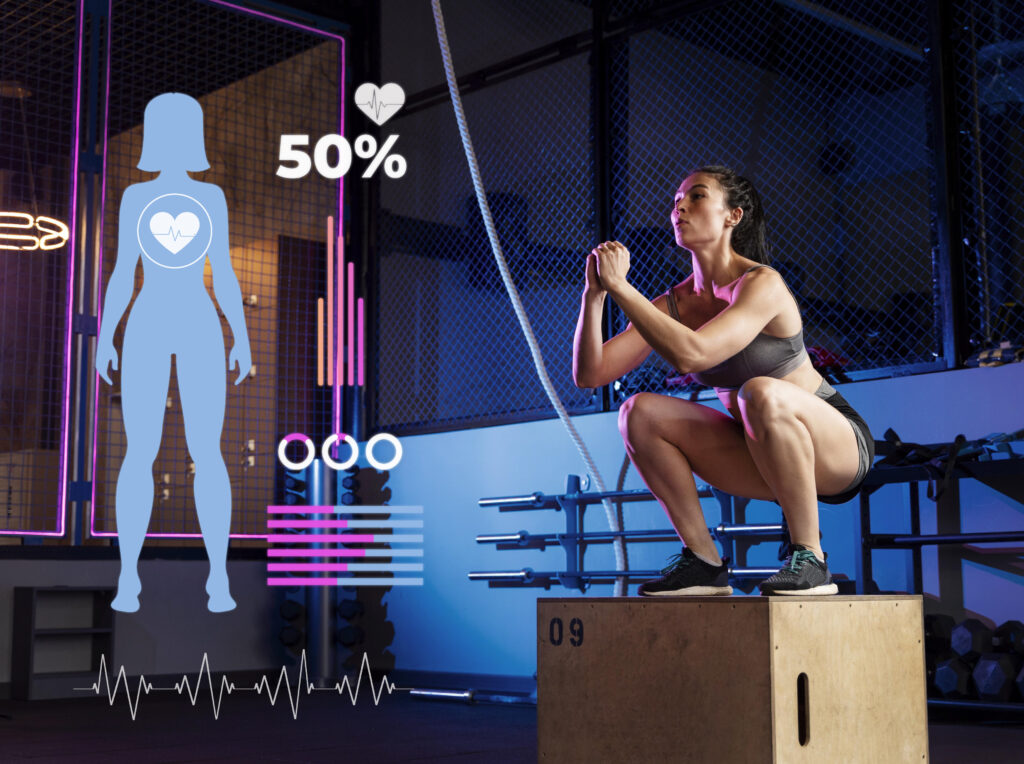

Through sensors, machine learning, and real-time monitoring, AI systems detect subtle changes in vibration, temperature, and performance. These small deviations are early indicators of potential problems. Maintenance teams receive alerts before damage becomes severe, allowing for timely repairs that prevent disruptions and extend equipment lifespan.

The Power of Data in Industrial Maintenance

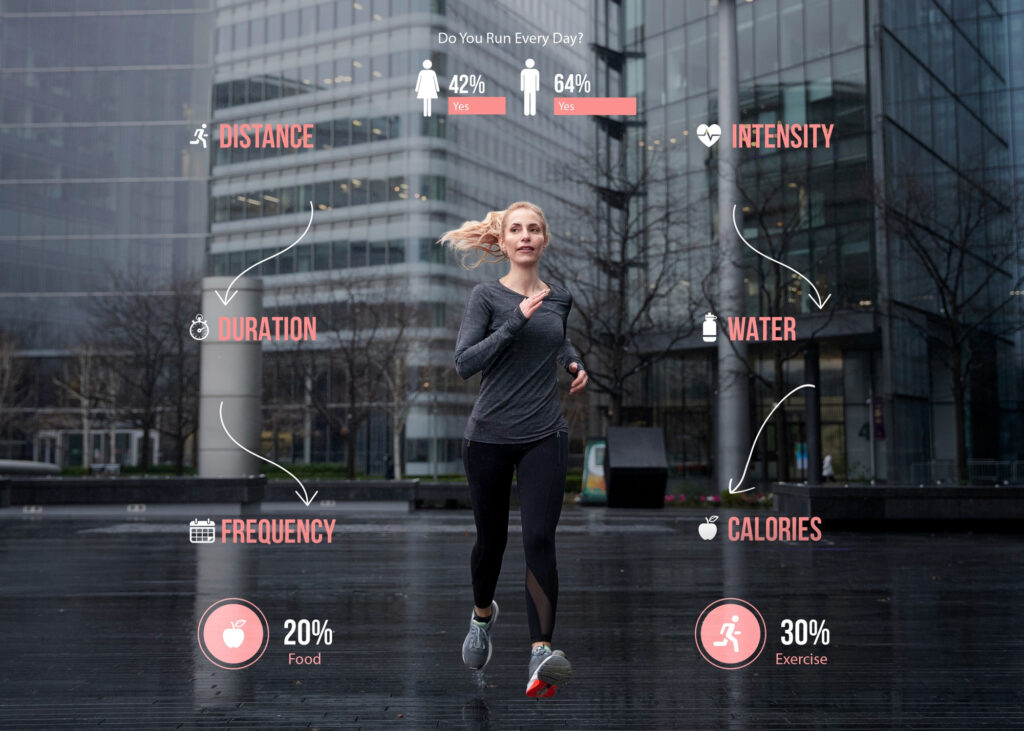

Every industrial machine generates a constant flow of operational data, from power usage to motion patterns. AI systems harness this data to uncover patterns invisible to the human eye. Algorithms learn what “normal” performance looks like and immediately recognize anomalies that may indicate wear, imbalance, or inefficiency.

This data-driven approach shifts maintenance from guesswork to precision science. Instead of relying on past experiences or visual inspection alone, technicians can make decisions supported by analytics. The result is higher accuracy in diagnostics, faster repairs, and a significant reduction in unplanned outages.

Machine Learning and Predictive Insights

Machine learning enables maintenance systems to continuously improve. By analyzing years of performance data, AI models refine their understanding of failure trends, component lifecycles, and usage patterns. Over time, the system becomes better at predicting issues and optimizing schedules.

For example, AI can analyze thousands of similar machines across facilities to determine which parts typically fail first or under what conditions. These insights guide procurement, staffing, and production planning, making operations more resilient and cost-effective. Each cycle of learning enhances efficiency, creating a feedback loop that drives consistent improvement.

The Role of IoT Sensors and Connectivity

The Internet of Things (IoT) is the nervous system of AI-powered maintenance. Sensors installed on machines capture real-time data about temperature, vibration, pressure, and more. This information flows into AI platforms where algorithms process and interpret it instantly.

Connectivity allows maintenance teams to monitor assets remotely, even across multiple sites. When an irregularity occurs, AI prioritizes it based on severity and operational impact. This level of awareness transforms maintenance into a proactive service, enabling teams to act strategically instead of reactively.

Reducing Downtime Through Automation

Downtime is one of the most expensive challenges in industrial environments. AI-driven systems minimize it by automating diagnostics, scheduling, and even certain repair tasks. Automated alerts ensure technicians know exactly which machines need attention and why.

Some advanced systems even trigger automated actions, such as slowing down machinery to prevent overheating or rebalancing loads in real time. This seamless integration between automation and maintenance keeps production lines running smoothly and prevents small problems from escalating into major breakdowns.

Enhancing Equipment Efficiency with AI Optimization

Beyond preventing failures, AI actively improves how equipment operates. By analyzing performance data, it identifies inefficiencies and recommends adjustments. For example, it may detect when a motor is consuming more power than necessary or when a conveyor’s speed can be optimized to reduce friction.

These micro-adjustments collectively lead to substantial energy savings and longer equipment life. AI essentially becomes a digital engineer, fine-tuning systems for maximum productivity and sustainability. The technology ensures machines don’t just function—they perform at their absolute best.

AI in Spare Parts Management and Supply Chain Efficiency

AI doesn’t stop at diagnostics—it extends into logistics and resource management. Predictive analytics can forecast which spare parts will be needed and when, ensuring inventory is stocked efficiently without overordering. This reduces both costs and waste.

For large operations, AI integrates with supply chain systems to automate restocking and supplier coordination. When a component nears the end of its life, the system can automatically generate purchase orders or schedule deliveries. The result is a maintenance ecosystem where machines, data, and materials operate in perfect sync.

Integrating Robotics into Maintenance Operations

Robotics and AI together are transforming maintenance tasks that once required manual labor. Drones and autonomous robots can now perform inspections in hazardous or hard-to-reach areas—pipes, turbines, and tall structures—reducing human risk.

These robots use AI vision systems to detect corrosion, cracks, or leaks that might go unnoticed. Combined with machine learning, they can also document and categorize findings, providing comprehensive maintenance reports in real time. Robotics makes inspections faster, safer, and more consistent across industrial environments.

Real-Time Analytics and Decision-Making

AI tools provide maintenance teams with live dashboards that visualize machine health, performance, and risk levels. This real-time insight empowers decision-makers to prioritize resources and interventions effectively. A single glance can reveal which assets are operating optimally and which require immediate attention.

Decision-making becomes faster and more informed. Instead of reacting to alarms or waiting for external analysis, maintenance managers can take immediate, data-backed action. These real-time insights are the backbone of agility in modern industrial environments.

Remote Monitoring and Cloud-Based Systems

Cloud technology allows AI-powered maintenance platforms to centralize data from multiple facilities. Remote monitoring systems can track thousands of machines simultaneously, providing a unified view of global operations.

This remote accessibility enables collaboration among teams across locations. Engineers, technicians, and analysts can share insights instantly, reducing response times and ensuring consistent maintenance standards. The ability to oversee assets from anywhere gives organizations greater control and flexibility, especially for complex or distributed operations.

Training the Workforce for AI-Driven Maintenance

As AI becomes more prevalent, the role of maintenance professionals is evolving. Instead of manual inspection, their work now involves interpreting data, managing automation, and optimizing systems. This shift requires new training in analytics, digital tools, and AI literacy.

Forward-thinking companies are investing in education programs to upskill technicians and engineers. Understanding AI outputs, configuring predictive systems, and troubleshooting digital platforms are becoming essential skills. The future of maintenance depends as much on human intelligence as artificial intelligence—working in harmony to drive performance.

Sustainability and Energy Optimization

AI contributes to sustainability by improving energy efficiency and reducing resource waste. Intelligent monitoring ensures machines operate within optimal parameters, minimizing excess power consumption and unnecessary wear.

By predicting failures early, AI reduces the environmental cost of replacements and repairs. Energy-efficient maintenance aligns with global efforts to reduce carbon emissions, making smart maintenance a crucial part of modern environmental responsibility. Efficiency and sustainability are no longer separate goals—they’re interdependent outcomes of intelligent design.

Cybersecurity and Industrial Resilience

As maintenance systems become more connected, cybersecurity has become a key priority. Networked equipment and cloud-based platforms create potential vulnerabilities if not properly secured. AI itself can help mitigate these risks by detecting unusual network behavior and blocking unauthorized access.

Industrial organizations are adopting layered security protocols that combine encryption, firewalls, and AI-based threat detection. The goal is resilience—not only preventing failures in machines but also in digital systems. Secure maintenance infrastructures protect operations, data, and trust in equal measure.

The Business Impact of AI Maintenance Systems

The adoption of AI-powered maintenance isn’t just a technical upgrade—it’s a strategic advantage. Reduced downtime, optimized energy use, and data-driven decision-making translate directly into higher productivity and profitability.

Companies that embrace AI maintenance are achieving better asset performance, lower operational costs, and stronger safety records. In competitive industries, these advantages can define leadership. Smart maintenance transforms maintenance departments from cost centers into engines of continuous improvement and innovation.

Conclusion: The Intelligent Future of Maintenance

AI is revolutionizing how industries repair, monitor, and sustain their most valuable assets. What once required reactive effort now operates with predictive intelligence, precision, and speed. Machines communicate their needs, data drives every decision, and maintenance becomes a science of foresight.

The combination of AI, IoT, and automation is creating a new era of industrial reliability—where downtime is rare, performance is optimized, and sustainability is achieved through intelligence. The factories of tomorrow won’t just run on power and machinery—they’ll run on data, insight, and the brilliance of smarter maintenance systems.